Bending the sides begins the process of making a guitar body. A bending form is required for each type and size of body, and the appropriate form is installed in the bending machine. This jig uses a heating blanket and spring loaded cauls to gently bend the sides to shape. The sides are carefully laid out and matched for best use of grain and figure prior to being bent. The bent sides are clamped into a building mold that is unique to each body type, and the head and end blocks are glued into place. A parabolic sander contours the top and back sides of the rims, and kerfing is installed to strengthen the rims and to provide more gluing surface for the top and back.

Bending the sides begins the process of making a guitar body. A bending form is required for each type and size of body, and the appropriate form is installed in the bending machine. This jig uses a heating blanket and spring loaded cauls to gently bend the sides to shape. The sides are carefully laid out and matched for best use of grain and figure prior to being bent. The bent sides are clamped into a building mold that is unique to each body type, and the head and end blocks are glued into place. A parabolic sander contours the top and back sides of the rims, and kerfing is installed to strengthen the rims and to provide more gluing surface for the top and back.

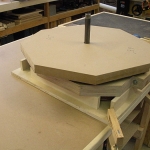

Dogwood Guitars are voiced and tuned as part of the boxing process. The braces are tapered to fit notches in the rims and the top is glued on. The top braces are carved while Greg voices and tunes the top using FFT analysis software to verify the progress. When the back and top are fully voiced and tuned to the correct fundamental resonances the back is glued on, closing the box. The back and top are flush cut and the box is sanded smooth. The photos below show the progress as a Monarch body is made.